How Does A Weigh Belt Feeder Work

Weigh belt feeders are used for conveying materials that are in the form of bulk solids or granular products. These products can be fed into the weigh belt feeder manually or by means of an automated conveyor system. The weigh belt feeder allows you to accurately measure material flow through your process line and provides a continuous stream of material to be processed.

What is a weigh belt feeder?

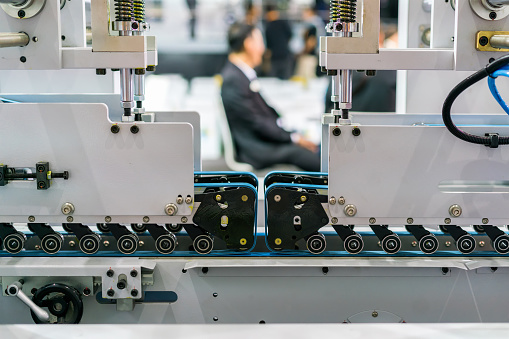

A weigh belt feeder is used to measure the weight of a product as it passes over a scale. The belt moves along on rollers and has channels for each individual product. As each product enters the channel, it is weighed and then moved past the scale so that another product can be weighed. A computerized system monitors each individual channel, ensuring accuracy and consistency in production processes.

What are its benefits?

- The most obvious benefit of using this type of machine is that you can produce products at high speeds with less labor cost than when using manual methods. You can also reduce damage or contamination during storage or transportation by being able to automate those processes as well.

- The direct, suspended load design of the weigh belt feeder eliminates the mechanical stresses related to the drive mechanism that is typical with other belts.

- This design eliminates the mechanical stresses related to the drive mechanism that is typical with other belts. The direct, suspended load design of the weigh belt feeder allows you to use more compact and less costly components than those associated with a traditional screw conveyor.

- Adding or removing material will not affect your belt speed/loading when compared with a screw system because it does not rely on an internal load-carrying device such as gears, chains, or pulleys. This means there are no moving parts to fail or wear out over time.

- Since you do not need any additional components attached to this type of feeder, it allows you maximum flexibility in how much material you want to move at one time by simply adjusting its length!

- Weigh Belt Feeder models are based on material weight-per-cubic foot, material weight-on-belt, desired feed rate in pounds per minute or tons per hour, and belt width.

- Weigh Belt Feeders are available in different models, depending on the material weight-per-cubic foot, material weight-on-belt and desired feed rate in pounds per minute or tons per hour. Some weigh belt feeder models also require a minimum belt width to operate properly.

Types of weigh belt feeders

There are two common types of weigh belt feeders: those that work using gravity and those that need electricity to function. Gravity units use a pull rod to move the product forward while electric units use an electromagnetic drive motor that moves the product by pushing against it with electromagnets inside the unit’s housing (usually called “grippers”).

Weigh belt feeders are typically short in length and are designed for static mounting or for incorporation into vibrating conveyor systems where dust might be an issue.